Column Structure 120 Ton Rubber Rugs Press Making Machine Rubber Mat Molding Compresss Machine

Description

Basic Info.

| Model NO. | XLB550*550/XLB1100*1100 |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Type | Rubber Mixer |

| Electric Parts | Chnt, Schneider, Siemens etc |

| Power | Electricity |

| Voltage | Customized |

| Certification | CE SGS BV |

| Structure | Horizontal |

| Useing Time | More Than 15 Years |

| Heating Method | Electric Heating |

| Hearing Plate Distance | 250mm |

| Working Layer | 1-4 |

| Plate Clearance | 150mm |

| Piston Stroke | 400mm |

| Heating Plate Quantity | 1-5 |

| Pressure | 120t or Customized |

| Heating Plate Size | 550*550*60 mm |

| Name | Rubber Mat Making Machine |

| Transport Package | Standard Package, by Sea |

| Specification | 20 CBM |

| Trademark | OULI |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 300 Sets Per Year |

Packaging & Delivery

Package Size 330.00cm * 120.00cm * 180.00cm Package Gross Weight 5600.000kgProduct Description

Column structure 120 Ton rubber rugs press making machine rubber mat molding compresss machine

Main Application :This machine is used to heat , vulcanize and solidify various kinds of rubber molded products,such as : rubber tile/rubber mat /gym floor mat/yoga mat/ anti vibration pad/snow plow scraper......

Basic introduction

Rubber vulcanizing press applies to all kinds of rubber (natural rubber, EPDM rubber, NBR rubber, synthetic rubber, silicone rubber ext. ) vulcanizing and compression molding.Rubber vulcanizing press can be used to make O ring, sealing parts, oil seal, auto parts, rubber crash pad, rubber air spring, key board, medical rubber parts, rubber bottle stopper, silicone wrist band, water-stop tape, bridge support/bridge bearings, rubber cable, electronics insulators etc..

Parameter of Column structure 120 Ton rubber rugs press making machine rubber mat molding compresss machine

| Parameter/model | XLB-DQ 550*550×4 | XLB-DQ 1100*1100*1 |

| Total Pressure(T) | 50 | 100/120/160 |

| Plate Size(mm) | 550*550*60 | 1100*1100*60 |

| Daylight(mm) | 150 | 150-300 |

| Daylight Qty | 4 | 1 |

| Piston Stroke(mm) | 400 | 150-300 |

| Main Motor Power(KW) | 2.2 | 5.5/7.5 |

| Overall Dimension(mm) | 1260×560×1650 | 1560*860*1850 |

| Weight(KG) | 3500 | 4000 |

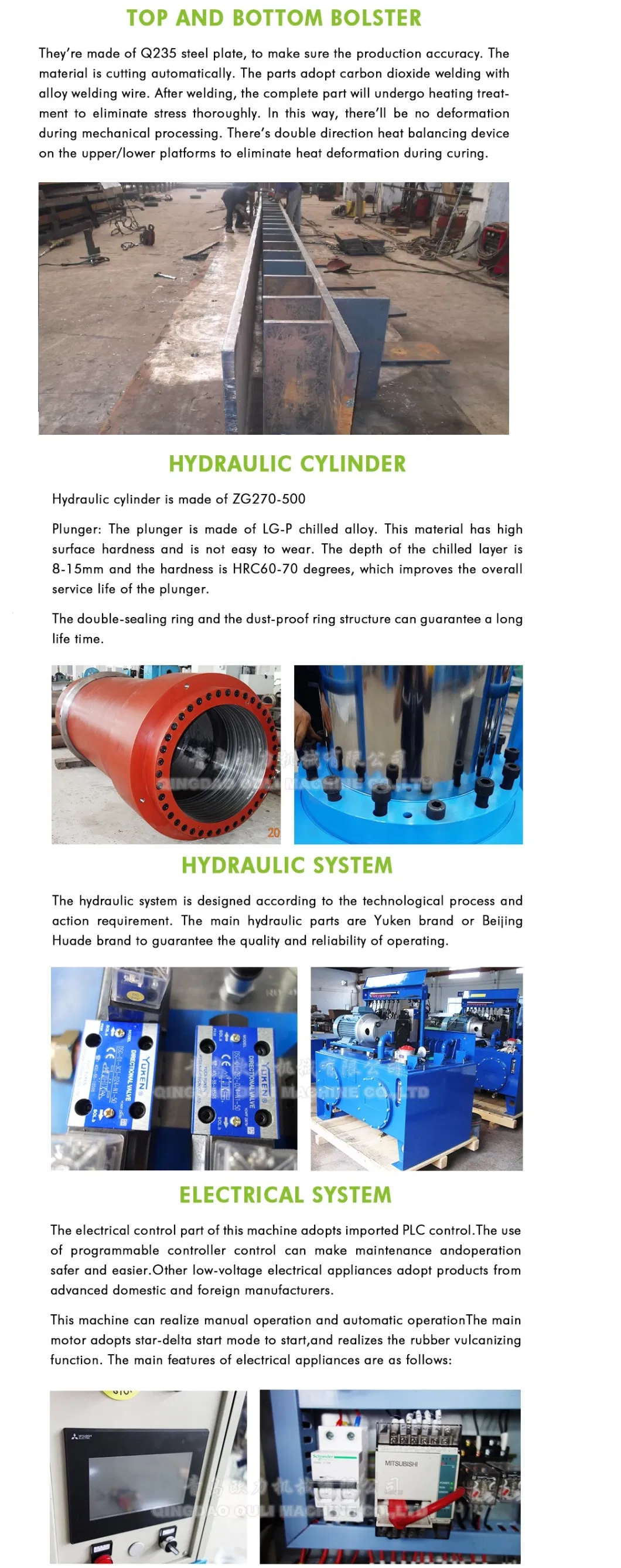

Important parts of Column structure 120 Ton rubber rugs press making machine rubber mat molding compresss machine

1---- Column Type and Frame Type 2---- Heating Plate

3----Top and Bottom Bolster 4----Hydraulic Cylinder

5----Hydraulic System 6---- Electrical System

Configuration of Column structure 120 Ton rubber rugs press making machine rubber mat molding compresss machine

1.The machine adopts the advanced PLC control . The working program can be set in the cabinet and machine will work according to this program2.Most spare parts for hydraulic system are imported from Taiwan3.Machine body casting is made of FCD 50 ductile cast iron ,which is processed by high tensile strength after aging passivation 4.The machine pillars/ columns are made of medium carbon steel , and its hardness can reach HRC55-585.The cartridge heater adopts three stages winding, nichrome wire , non-rusty 6.Oil seal are from Japanese NOK and Sakagmi Brand , it is wear-resisitant ,durable and oil tight7.Main electrical elements are from Schneider France ,which can stabilize machine performance

Sample pictures of Column structure 120 Ton rubber rugs press making machine rubber mat molding compresss machine

More introduction about the rubber pressing machine(Column Type Press and Frame Type Press)

The process to make rubber and silicone products includes: material preparation,kneadering,mixing, preformer, cutting,calendaring, vulcanizing and machining etc.Every step needs specific equipment and technology to complete.Qingdao OULI machines with the best control on temperature and pressure can provide precise parameter in vulcanizing process.The frame design can be divided into compression machine, injection machine and continuous vulcanization machine.As to the needs from varied molding products, we apply total solutions in the material feeding, clamping, moving and demolding design.For some products with high volume requirement, the vulcanizing machine can be your best choice based on speed and production.

Advantages of Column structure 120 Ton rubber rugs press making machine rubber mat molding compresss machine

No.1 Customized design heavy duty (large tonnage) vulcanization equipment is available, production capacity up to 11000 tons. No.2 Central control / system by PLC and touch screen controller.No.3 Equipped with cooling system on the bottom of cylinders to prevent oil temperature rise and maintain better endurance operation.No.4 The bottom of cylinders is contacted to platen with full pressing area to have even pressure and better product quality.No.5 The seal of cylinders is located far from platen to have longer life cycle.No.6 Top cap of cylinders is designed with oil return hole to prevent product polluted from leakingNo.7 Customized heating platen size design available.

Eight/8 Steps of making Column structure 120 Ton rubber rugs press making machine rubber mat molding compresss machine

1--- Laser cutting what we need 2---Welding parts

3--- Flaw detection to ensure quality 4--- Annealing

5--- Maching 6--- Assembling

7--- Inspection 8--- Finished product

Except Rubber Vulcanizing press machine , we have many other products related to rubber production.Such as Rubber Kneader,Rubber Bale Cutter, Batch-off Cooling Machine , Rubber Calender, Rubber Extruder, Tube Extruding Line,Tube Curing Press Machine, Waste Tire Cutting Machine ,Rubber Crusher ,Tire Shredding Machine ,Rubber Powder Grinder ,Reclaimed Rubber Refining Mill ......

About the Package and delivery

With professional equipments and workers, we can pack Column structure 120 Ton rubber rugs press making machine rubber mat molding compresss machine in time. The following pictures are some of the package.

Our advantages

Brief Introduction of OULI Company

Work show & Certification

With more than 20 years experience in this field ,we have customers all around the word .

Our products have been exported to many countries ,such as America ,France ,Canada ,Australis ,Sotheast Asia ......With high quality and excellent service ,our products have won highly praise from customers.

More information abou us : 1---What about delivery date? It depends on the quantity of machine you ordered. Usually it will take20-30 days after getting deposit to ship to your country. Accept urgent order for prompt shipment. 2---What's the warranty statement?OuLi machine warrants all the products manufactured by OuLi machine to free from defects in material and workmanship Under normal use of a period of 12 months or 36months after the date of the original purchase price if repair or replacement is not possible of practical, OuLi machine will assume no liability for labor costs, installation costs, or other losses. Your warranty rights will be honored Only when the product has been installed and used properly as deemed by OuLi machine,OuLi machine will not repair products damaged by improper use or faulty installation.3---What about OULI oversea service ? OULI will arrange oversea setting up and training works if customer need . Customer should pay for accommodation , tickets and salary . Meanwhile OULI has branches in different areas like north America , Southeast Asia , Brazil etc , etc . All above is the description of Column structure 120 Ton rubber rugs press making machine rubber mat molding compresss machine.If you are interested in it , just send me email or inquiry, I can give you professional information and good price.

Our Contact